Enterprise Material Master Data Management/Governance

Why and How IBA Group Created IBA HOTD

As a longtime partner and solution provider of SAP AG, IBA Group has been delivering enterprise master data management solutions based on SAP MDM since 2012 and has begun delivering solutions on SAP MDG shortly after its inception in 2011.

In most cases, we do not implement solutions from scratch, because by the time a customer makes a decision to clean up their master data, they accumulate a significant amount of legacy data, including material master data. As the number of duplicate, incorrect, inconsistent, and irrelevant records in the legacy material master data is typically enormous, conversion brings about a 2-3-fold reduction in master data volumes.

When implementing SAP MDM / MDG solutions, customers incur significant costs on normalization of source master data and preparation of golden records to be loaded into SAP MDM / MDG systems before their commercial operation.

One of the key problems in the creation of master data is identification of a material master record. A common practice in building legacy master data was the use of short names for the materials coming from shipping documents.

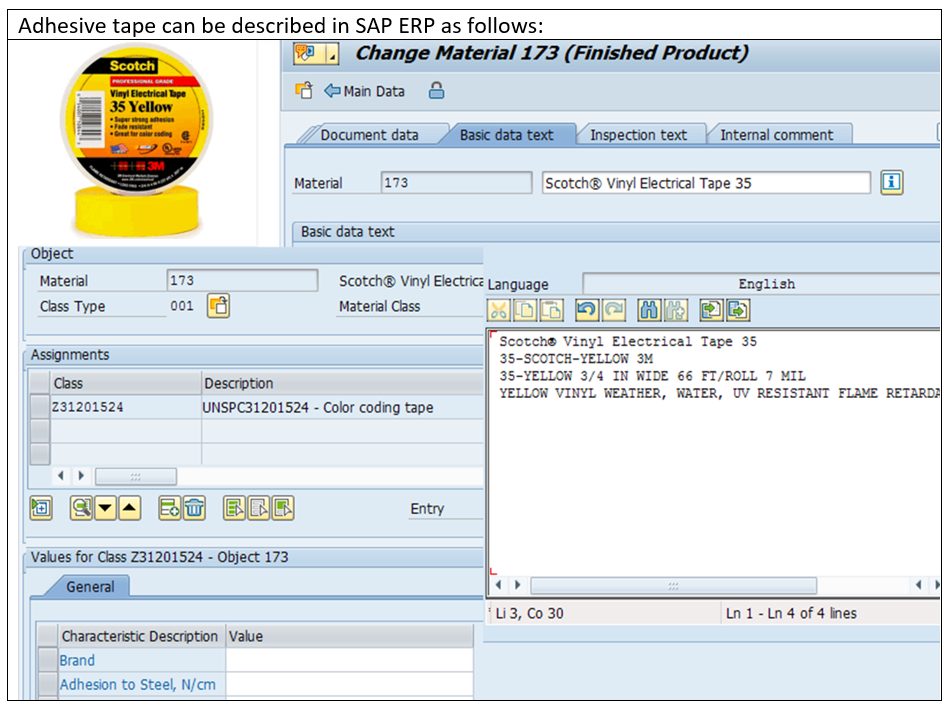

Example

The characteristics of this tape are presented in a free text format, which is acceptable for human perception, but not suitable for automatic processing. For automatic processing tasks like search or purchase of a material with a set of specific values, a unified description structure is required. Creation of a description structure involves building a Classifier in the form of a taxonomy or ontology, presented as a tree of nodes and a set of characteristics inherent for each of the nodes.

SAP ERP, SAP MDG, and SAP HANA ERP / MDG provide the tools needed for creating and maintaining a corporate classifier. However, in most cases, verified records must be prepared and loaded into the system before one can use the tools.

Typically, it is possible to create correct data through the extraction of material-forming characteristics based on their values. In the example with the tape, such characteristics are Brand (Scotch), Tape Thickness (18 mm), Tape Material (Polyvinyl Chloride, Vinyl), Breaking Strength (30 N/cm), Color (Yellow), and others.

From a brief description of the tape Scotch Vinyl Electrical Tape 35, one cannot identify the values of the characteristics without an additional description. Because of lack of detail, this tape name can be associated with a number of tapes with different characteristics.

If different incoming materials are registered with the same name Scotch Vinyl Electrical Tape 35 as a unique identifier, it results in data inconsistency. This causes confusion when it is required to transfer a specific material to production.

Another shortcoming of identification by short name is that it may lead to the creation of duplicate entries. Small variations in the short name may result in duplication. For example, one can put Scotch Vinyl El.Tape 35 or use different measurement units for the same material.

If there are duplicates in the system, especially with different measurement units, companies cannot make estimates of their stocks for a specific material and hence correctly replenish the stock. Most often, losses occur due to excessive purchases and storage of excessive amounts of materials in warehouses.

Various groups of specialists made significant efforts to solve the identification problem at the methodological level and in practice, resulting in the creation of relevant ISO standards and systems.

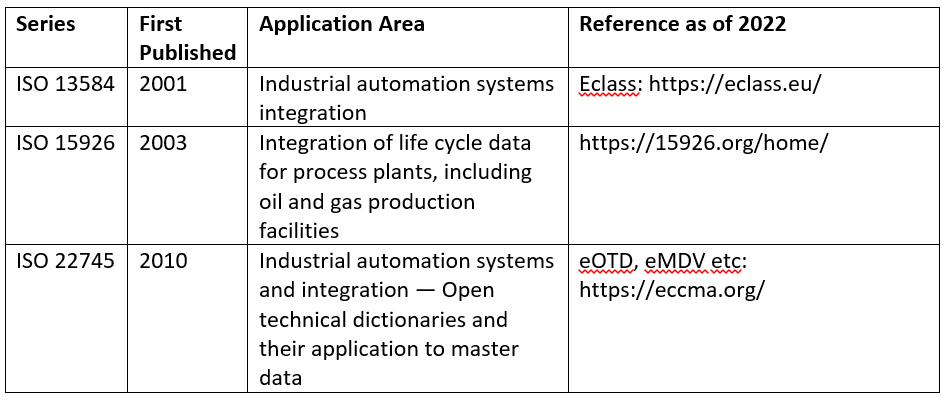

The table below lists some of the most well-known series of ISO standards and systems designed to solve the identification problem, including those applicable to the implementation of material master data management systems in corporate information systems.

In 2014, IBA Group began its own research and development related to identification and description of golden records for master data in materials and business partner domains.

Our experience of implementing master data management systems on SAP MDM/MDG for IBA Group customers revealed that data quality has been deteriorating over time even with the companies that used SAP MDM/MDG.

A radical way to solve the problem of data quality deterioration is a periodic (every few years) restart of the project with a one-time re-normalization of master data.

An intermediate solution is to assign a master data management group (information stewards), having the responsibility of periodic (several times a year, for example, quarterly) data quality audits and corrective actions to eliminate duplicate, incorrect, inconsistent, and irrelevant records.

A root-cause analysis of data quality deterioration revealed that the key source of the problem lies in the concept of building corporate classifiers based on internal data sources, namely shipping documents and personal experience of business experts who create or make changes in the master data, including selection of material-forming characteristics.

Furthermore, if each company has its individual corporate classifier with specific characteristics, this makes it difficult or impossible to automate the exchange of data in the logistics chains. A provider needs to configure mappings between characteristics of supplies of companies using different classifiers.

To organize data exchange, it is possible to assign codes to classifier nodes and characteristics in accordance with Eclass/ISO 13584 or eOTD/ISO 22745, when building a material master data classifier and golden records. However, this can significantly increase labor efforts and costs at the stage of the initial data preparation for uploading.

Another problem appears when suppliers and manufacturers are the primary sources of characteristics. For example, in eOTD different suppliers or manufacturers can register the same characteristic of similar items with different codes.

IBA Group’s research and development efforts in the normalization of corporate master data resulted in the creation of the IBA HOTD (Harmonized Ontological Technical Dictionary) system. We released the first IBA HOTD version in 2016.

The IBA HOTD architecture sums up IBA Group’s experience in implementing and operating of material master data management systems for IBA clients and partners.

The architecture of IBA HOTD is built on the following principles:

- International standards are reliable sources of data on supply items. All records on products manufactured by different companies receive a unified set of characteristics, automatically harmonized between companies.

- The standards’ classifier serves as the basic classifier. Any other classification features are added as attributes.

- RDF/OWL ontologies are used as a formalism to represent the information contained in the texts of the standards. This provides the necessary flexibility to describe products, their parameters/attributes, and combinations of characteristic values. It also allows for a smart search of records based on a set of values of parameters/attributes.

To date, the IBA HOTD system includes the following components:

- For the content creation process, a standing group of data experts (stewards) in cooperation with standardization organizations performs digital transformation of the texts of national and industry standards into the OWL/RDF ontologies

- IBA HOTD contains approximately 1,000 OWL/RDF ontologies created from texts of standards (some of them are originated from ISO) using specific OWL/RDF ontology template

- The server part is a set of RESTful API services that provide access to data and functionality, including an internal interface to the SPARQL endpoint on Apache Jena Fuseki. Any other platform can be used, including Blazegraph, Stardog, and Topbraid

- The frontend part provides an end-user interface to HOTD services and includes the smart search functionality. It consists of the following two components:

- HOTD App Web Application

- SAP ERP/MDG add-on

HOTD App is a web application designed to build material master data classifiers and golden records within one-time normalization projects.

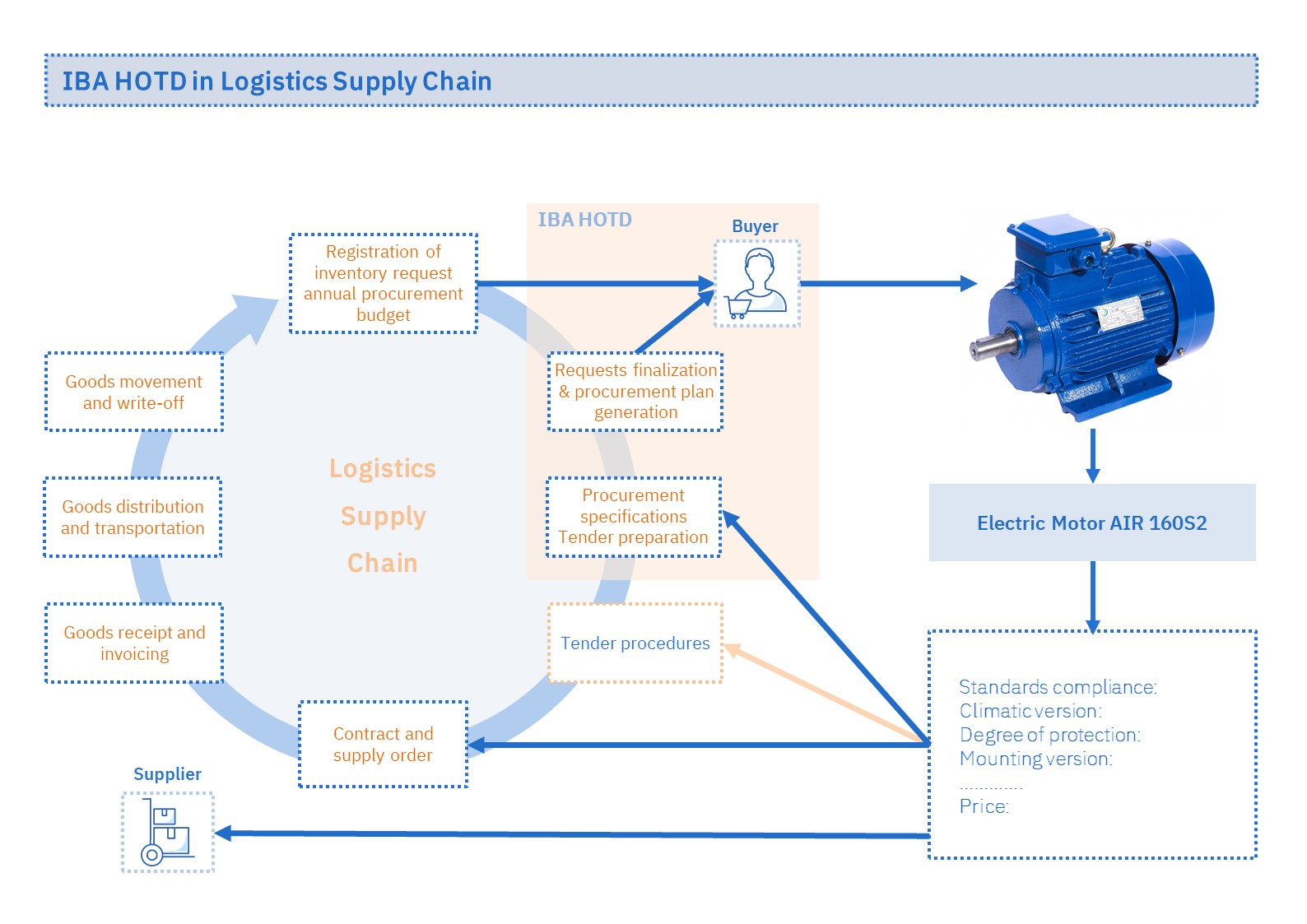

IBA HOTD SAP ERP/MDG add-on is designed for conducting data quality assurance activities using an incremental (superseding) normalization scenario.

With incremental/superseding scenario, the normalization of master data is carried out in parallel with the normal work of the SAP ERP system, replacing step-by-step the outdated, incorrect, and duplicate records with the golden records. This approach does not require an additional budget or additional efforts by business experts.

The key prerequisite for this scenario is an external trusted source of golden records, including characteristics of items. Depending on the customer’s needs, Eclass/ISO 13584, eOTD/eDRR/ISO 22745 or IBA HOTD (based on digital images/ontologies of ISO/ASTM/etc. standards) can be considered as a trusted source.

The trial operation of IBA HOTD has confirmed its efficacy in terms of data quality for different companies, including those that cannot afford full-scale implementation of master data management systems on SAP MDG.

Reach us, if you want to implement IBA HOTD in your company or to know more about IBA Group’s experience in implementing and operating material master data management systems, and how we can help your business be more structured and run smoothly.