Material Master Data Normalization and Golden Records for SAP MDG

As a long-term partner and solution provider of SAP AG, IBA Group has been delivering enterprise master data management solutions using SAP MDM since 2012 and SAP MDG since 2015.

When implementing SAP MDM and eventually SAP MDG solutions, we at IBA Group developed practical recommendations on how to represent material master data in SAP. In this article, I would like to give an overview of these recommendations.

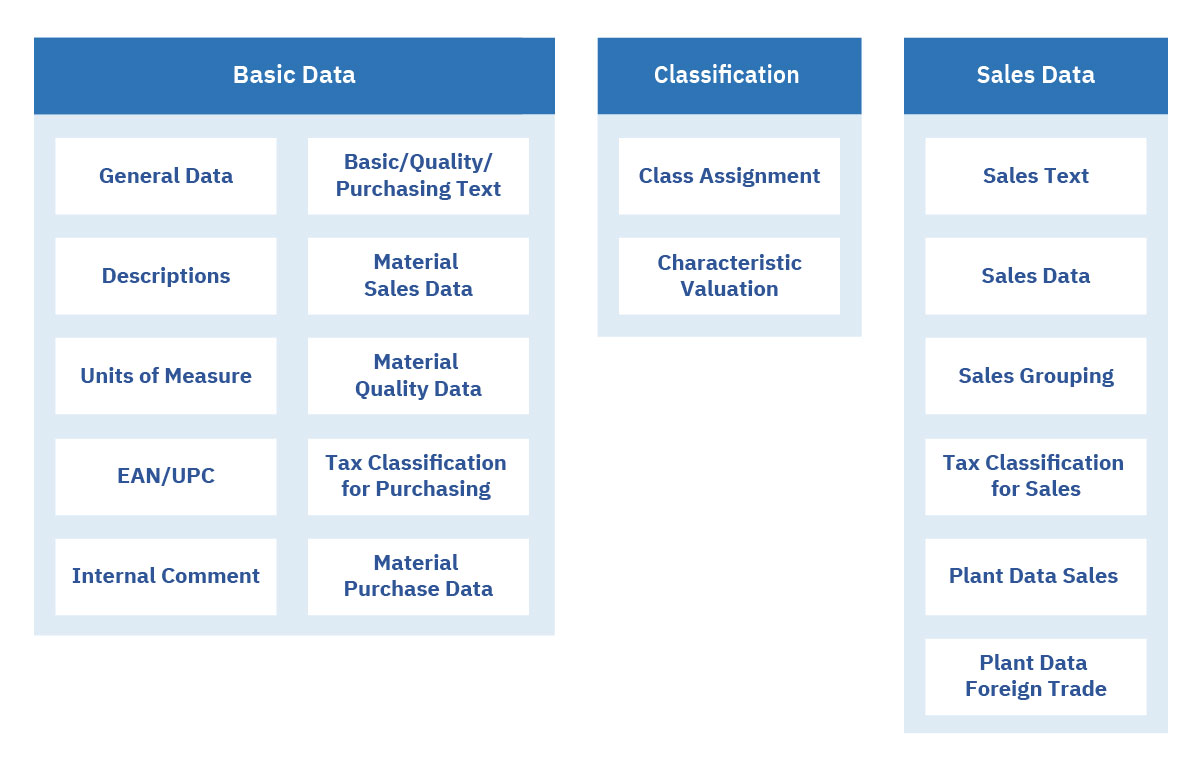

The preconfigured MDG-M material data model supplied with SAP MDG is quite complex, as it includes various aspects of information that may be needed to run transactional systems.

The following figure shows the complexity of the SAP MDG-M material master data model.

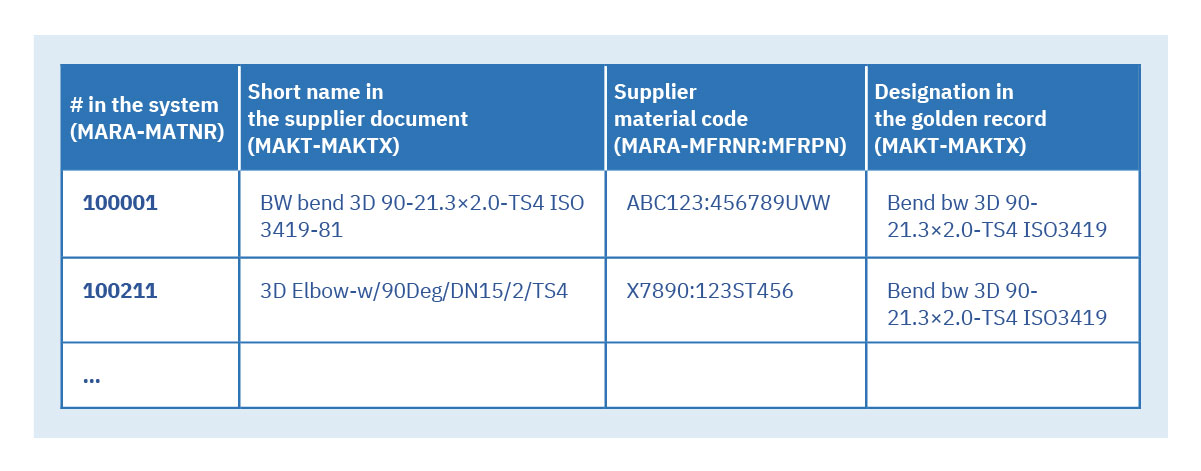

The principal task of representing SAP material master data is the correct identification of each material. The key attribute of a material record in SAP is its unique number (MARA-MATNR). However, two material records having different numbers in the system might be considered as representative of the same material from the point of view of a business user, like warehouse or equipment maintenance personnel. In SAP MDM/MDG, such materials must be represented by one golden record. All other records are duplicates and must be excluded during the normalization process.

You can see examples of golden records of materials in the table below.

Where do duplicates come from?

The source of the duplicates may be related to the business process of entering the material master data, where a new record is created while processing shipping documents or a price list of a supplier or manufacturer and the identification name of a material is copied from the matching source document.

It is possible to identify material golden records during normalization (deduplication) in various ways. One of the methods is based on unique numbers in manufacturers’ catalogs. However, with this method, it may happen that competing manufacturers produce a similar product, corresponding to requirements of the same set of standards (ISO, ASTM, ASME etc.), but in their catalogs the product receives different numbers. Another problem is caused by the nature of item number in a catalog. As a rule, it is not human-readable. It leads to cases, when a small mistake in one digit or letter forms a wrong number, and a business user has to spend some time in order to make sure that a record in the system corresponds to the appropriate item in the catalog.

To avoid this problem, we can identify materials by the list of key attributes and their values. The list of key material attributes and their values can be generated either directly from the content of the records, or with the involvement of external specialized data sources.

For example, for entries from the above table, a business user can visually determine the attributes of fittings, including the fitting type (bend or elbow, reducer, tee, cap), OD (outside diameter in millimeters – 21.3), DN (Nominal Diameter – 15), WT (wall thickness in millimeters – 2.0), fitting angle in degrees (Bend angle in degrees – 90), and geometry type (2D or 3D) .

We can also identify material attributes using company price lists or internet sources. If we use specialized external sources, such as ECCMA eOTD or IBA HOTD, the attributes’ composition complies with international standards that address product description in supply chains.

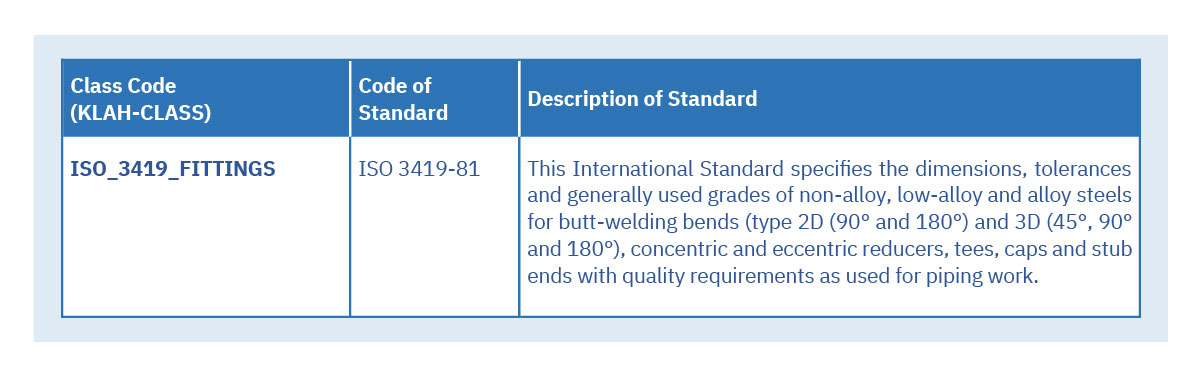

To identify materials by attribute, we at IBA Group use the 001 type classifier in SAP ERP/MDG, based on KLAH, CABN, CAWN, and related tables.

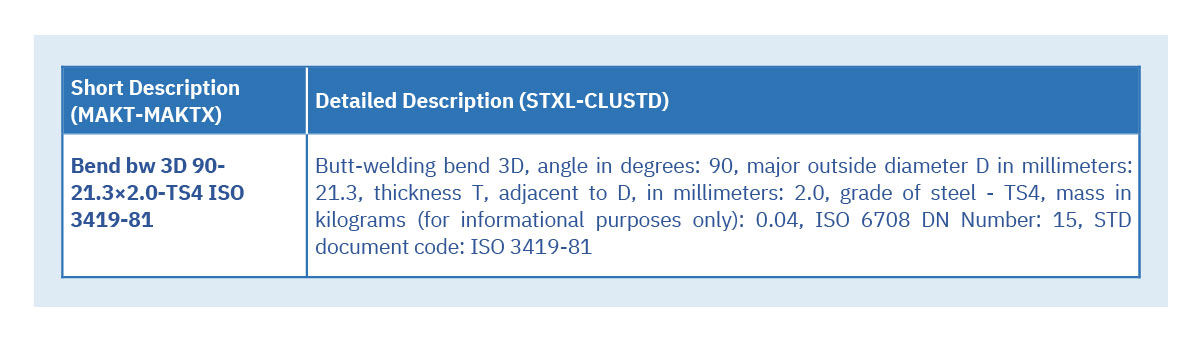

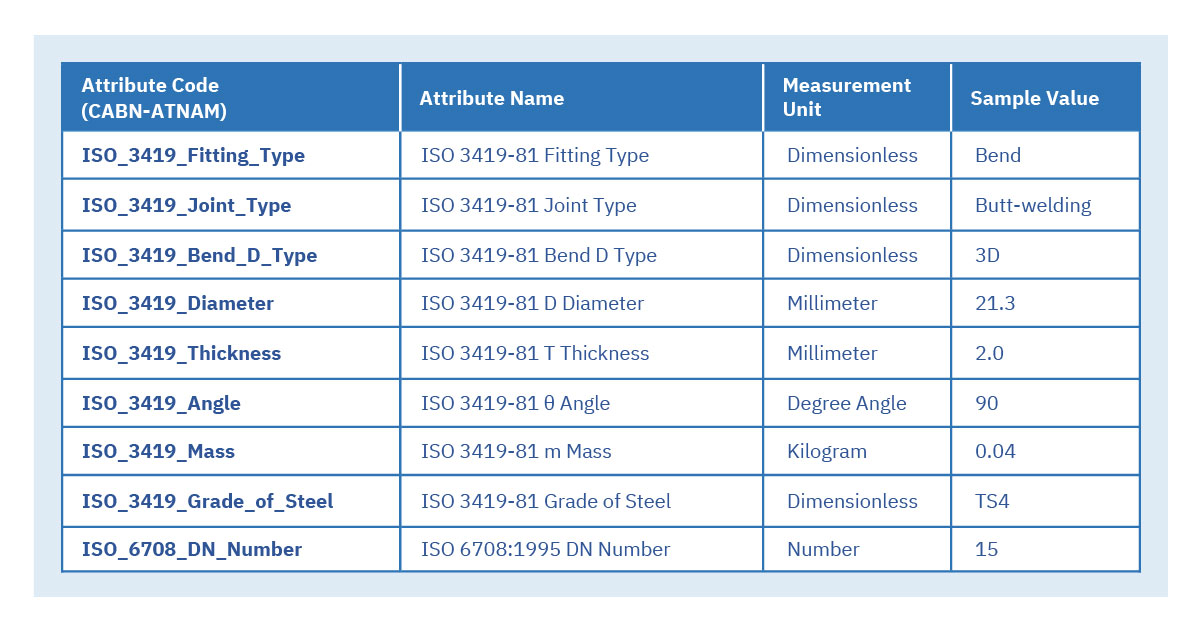

For example, it is possible to represent the key material attributes from the above table in the fields of the SAP ERP 001 classifier, as shown in the following tables.

The attribute code and name in the IBA HOTD system contains reference to specific standard code (ISO 3419, ISO 6708 in this case), describing the material. It allows for unique identification of the attribute name, unit of measurement, and domain of values for the attribute in the system.

If the IBA HOTD ERP/MDG add-on is installed in your SAP ERP/MDG solution and has a ZHOTD search feature, it is possible to get the description of a material using the search string, such as Bend 3D 90 21 2 TS9. The string returns material description structured by attribute as shown above. The IBA HOTD ERP/MDG add-on also includes the transaction ZHOTD2ERP, which allows a user to transfer this structured description to the SAP ERP classifier and then use it for SAP material master data with automatic generation of short and full material names, as well as checking for duplicates.

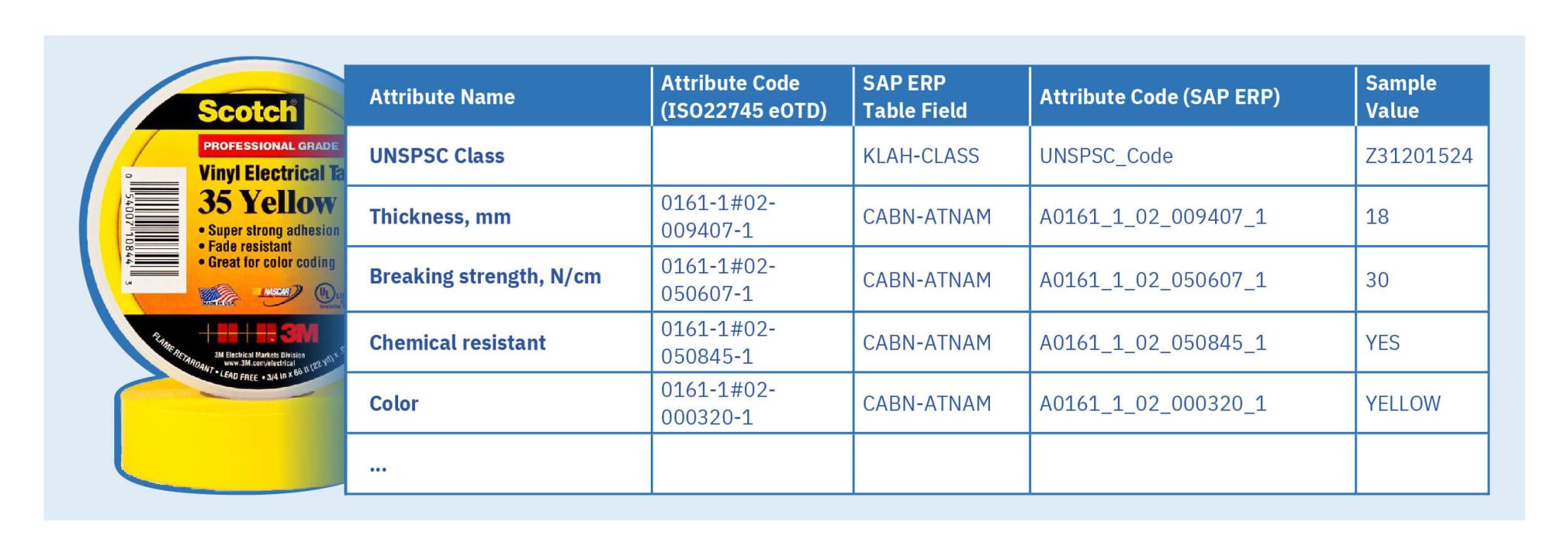

Similarly, we can present a material using the open technical dictionary (eOTD.org), created and maintained by the ECCMA (eccma.org) association. Each material property in eOTD.org has a unique identifier, with which the material property (attribute) can be encoded in the SAP ERP/MDG classifier.

The table below shows how the Scotch vinyl electrical tape can be represented in the SAP system.

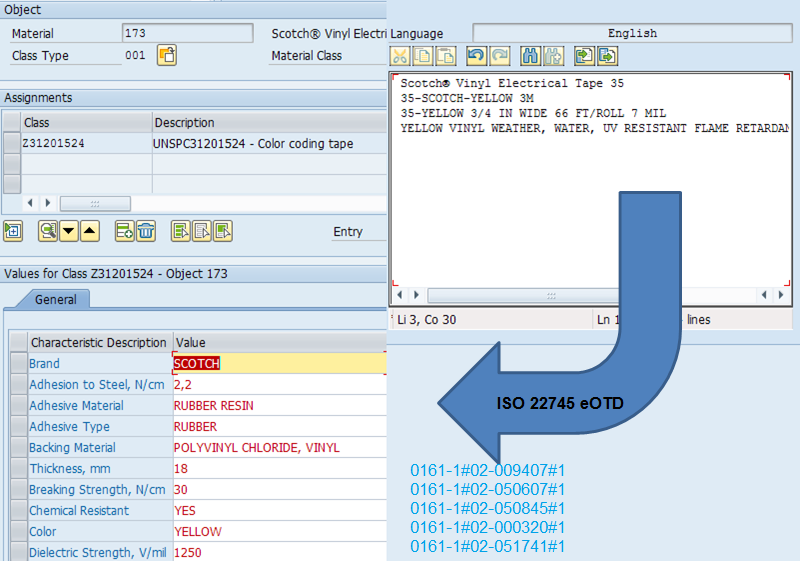

The following figure shows material description using MM03 transaction (combination of several screens, for illustration purpose only).

Thus, structuring of information about a material with the use of a list of attributes and possible attribute values, and their subsequent storage in the 001 classifier of SAP ERP / MDG allows us to create and maintain golden records for material master data at a high quality level.

The use of specialized external sources of data on the attributes of materials and their possible values reduces labor costs for the identification and description of material attributes and values. Creating and maintaining high quality golden records of materials, large-scale companies achieve significant savings in their procurement budgets due to elimination of duplicate purchases and minimization of storage costs for the surplus materials.

Read Vladimir’s previous thoughts on enterprise material master data management/governance.

Reach us, if you want to prepare your material master data for SAP MDG or to know more about IBA Group’s experience in implementing and operating material master data management systems.